|

CONSTRUCTION OF LOCUST |

|

|

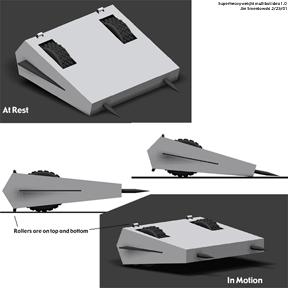

The original concept design for Locust was modified a few times, but stayed basically consistent throughout the building process. I wanted a super-fast, invertible and sturdy ramming machine with two spike 'mandibles'. The original concept was for more of a wedge shape, but after discussing with Stephen and Paul that they were going to build wedge-shaped bots for their thirds of The Swarm, I decided to go a different (and easy) route and build a simple box shape instead. |

|

|

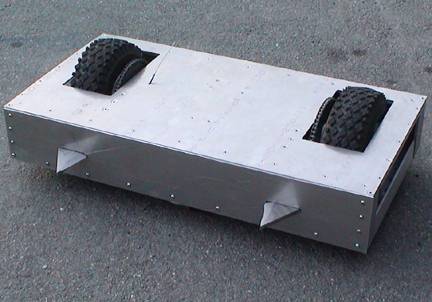

I started with a baseplate of .25" 6061 T6 aluminum and added several internal braces and supports to compose the rigid frame. Battery bays and rigid motor mounts were built sandwiched between the top and bottom plates. I used more quarter and half inch aluminum in this robot than any other I have built in the past. After all, this thing has to be able to take abuse from robots 3X as heavy! The wheels were placed on stationary shafts, utilizing the built-in bearings of the wheels I had available. |

|

|

I knew these bots would have to deal with some tremendous forces, fighting robots three times their own size, so this time I decided to go with a shock-mounting device for my RDFR38e Vantec speed controller. These rubber shock mounts kept the impact force from being transferred into the Vantec's case. |

|

|

The battery bays are secured from all sides and are padded for protection against impact shock. Not much in this robot to look at, but then again, the less complex the machine, the fewer parts there are to fail in combat. I know, famous last words..... |

|

|

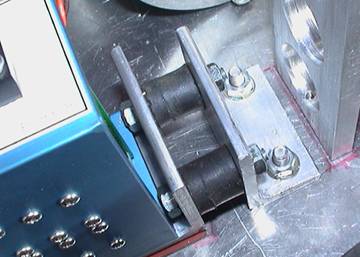

A closer view of the drive sprocket on the wheel. I have since swapped out the smaller #35 chain and sprocket with a new dual-stage geardown system involving spur gears and #40 chain sprockets. |

|

|

The steel teeth on the front were mounted securely to Locust's frame. The teeth were constructed sharp at the point and inside, for that special 'grab and rip' action! |

|

|

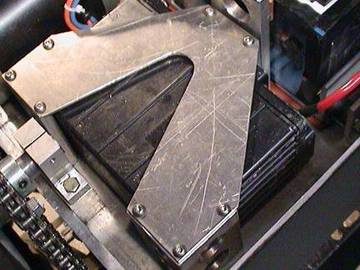

Roller "wheelie bars" were added to the back, because Locust takes off so quickly that he scrapes the back corner against the ground. You will notice that Stephen Felk's craftsmanship has had an influence on me, as I used nearly 500 machine screws, all tapped and countersunk, in this bot. Thanks, Stephen. Ugh. |

|

|

Locust in his near-final stage, ready for testing and a paint job! Not bad for less than 2 weeks' work. Final weight of Locust for Season 3.0: 108 lbs. |

|